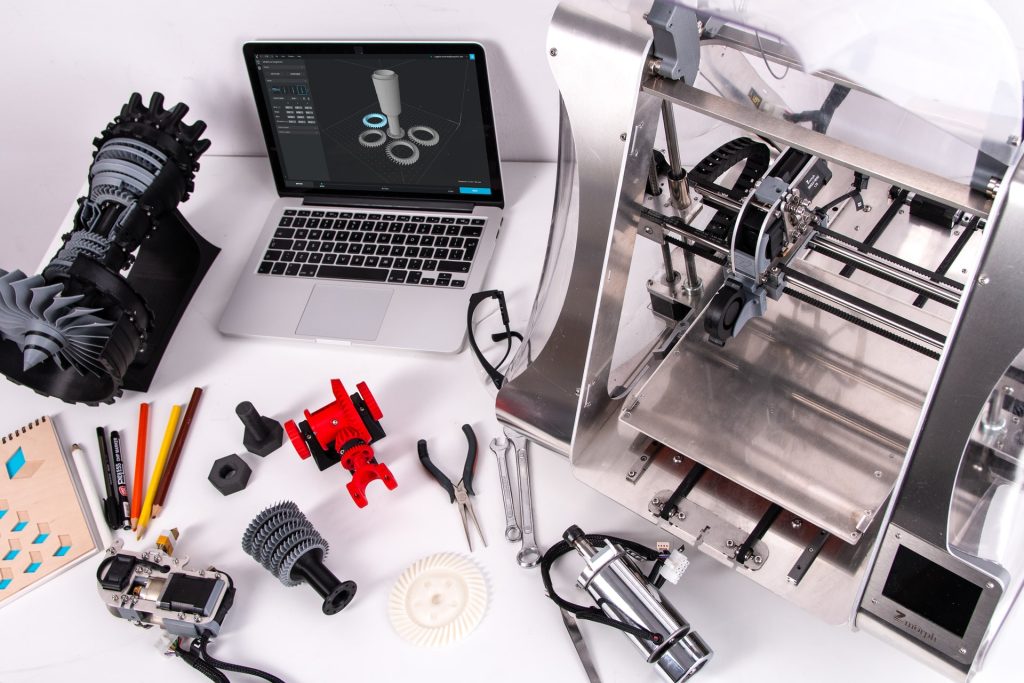

To get started with your very own 3D printing studio, the three main elements that you need are design software, the printer unit itself, and 3D printer filament to load in there, like the ink or toner in a regular printer. The filament is what is heated and reshaped into whatever object you’ve designed using your software program.

But is 3D printer filament like that of ink and toner cartridges for regular printers? Is it a case of buying certain types of filament for different 3D printer types? Or does it all work in a one-size-fits-all kind of way? Let’s take a closer look and try to answer those questions.

Printing Without an Enclosure

Having an enclosure built into the printer was one of the factors that made 3D printers so expensive both to make and ship.

Now that more consumer-friendly models have been created without the need for an enclosure, the printers are both cheaper and easier to get one’s hands-on. But removing that enclosure wasn’t an arbitrary choice. It had to be carefully thought through.

The problem is that using some filaments in the 3D printing process generates fumes that can be dangerous if not properly ventilated or protected against. The enclosure is designed to contain those fumes. What’s more, the enclosure also protects the printing process from draft winds and dust.

While some filaments still require an enclosure (see below for more), many have been developed that work very safely without.

If you’re printing without an enclosure, then you are generally safe to any of the following printing filaments:

- Polylactic Acid (PLA)

- Polyethylene Terephthalate Glycol (PETG)

- Thermoplastic Elastomer (TPE)

- Thermoplastic Polyurethane (TPU)

If you’re using ASA or ABS without an enclosure, it’s only suitable for use in very small and simple projects that will print relatively quickly. Otherwise, it’s essential to use these with an enclosure.

Printing With an Enclosure

Using the two filaments we mentioned just above warrants the addition of a proper enclosure for the work. Acrylonitrile styrene acrylate (ASA) and acrylonitrile butadiene styrene (ABS) not only require stable temperatures provided by an enclosure. They will also warp and fail to print correctly if the enclosure is unavailable.

If you buy a printer without an enclosure because you mostly print with materials that don’t require it, but then decide to use ASA or ABS in one job, even if it’s just for a one-time project, there’s no need to throw away your enclosure-less 3D printer.

You can purchase aftermarket enclosures, even ones that fold up into handily portable and storable units. In this way, you can whip out the enclosure when you need it, but it doesn’t have to become a huge additional expense or a new printer.

The Maximum Extrusion Temperature of Your Printer

The maximum printing temperature that your printer can handle will also bear what kind of filament you will ultimately use. Key components around the extruder nozzle, such as the PTFE tube, may have limited tolerance for higher temperatures depending on their overall quality.

Suppose you’ve bought a budget home 3D printer. In that case, the chances are that it won’t be able to handle the use of PC-ABS, Polycarbonate, and some other thermoplastics because it can’t handle the temperatures required to create items that industrial 3D printers can handle.

Therefore, always inspect these maximuFilamentm temperatures, and as the vendor of your 3D printer for more information about suitable filament types. The chances are that the same vendor sells filament or connects to a good store. It’s in their interest to recommend filaments that will deliver good results.